Corrosion-proof materials, mechanical resistance, and total sealing as keys to reducing interventions and extending service life

Why maintenance-free durability is a critical factor in outdoor lighting

ARRE —16/7/2025— When discussing public lighting, energy efficiency often takes the spotlight. However, another factor directly impacts the technical and economic sustainability of a project: system durability without the need for maintenance.

Corrosion, salt, humidity, UV radiation, vandalism, airborne dust, sudden thermal changes… All these agents, commonly present outdoors, rapidly degrade materials and components if they are not properly selected. The result: service interruptions, unexpected operational costs, and loss of reliability.

This article explores how to design installations that operate continuously and without periodic interventions, even in adverse conditions, and which technical elements directly influence that durability.

Material selection: a structural decision

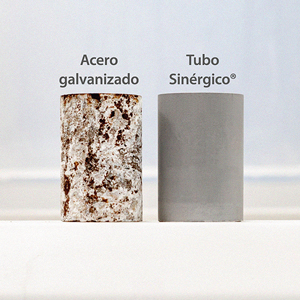

One of the most critical aspects for ensuring the resistance of a lighting system is the composition of its structure. Traditionally, materials like steel or aluminum have been used, but their performance against corrosion or marine environments is limited without constant protective treatments.

However, some materials are specifically developed to permanently withstand these conditions without additional coatings. Such is the case with the engineering polymers used by ATP Lighting (S7 and T5), successfully tested in salt spray, UV, and climate chambers:

- S7, used in poles and chassis, offers corrosion immunity, thermal stability, fire resistance, and zero electrical conductivity

- T5, applied in diffusers, provides high light transmittance, great impact resistance, and stability against solar radiation.

Using these materials eliminates corrective maintenance related to oxidation, sealing loss, or structural degradation, even after years of direct exposure to aggressive environments.

True sealing: beyond the optical assembly

Another often underestimated aspect is enclosure sealing. While many luminaires claim high IP ratings, these typically only apply to the optical compartment. Dust, moisture, or insects can infiltrate through joints, covers, or connections if the design doesn’t ensure integral protection.

Some solutions, like those developed by ATP, apply the IP66 rating to the entire structure: body, gasket, diffuser, and service doors. Moreover, they use robotized continuous sealing systems without joints, minimizing the risk of sealing loss over time.

In environments with constant humidity, frequent rainfall, salinity, or airborne sand, such integral sealing makes the difference between a reliable system and one that starts failing within months.

Withstanding daily use and vandalism: the role of IK rating

Impact resistance is key to durability, especially in urban, sports, or pedestrian areas. The IK standard (IEC 62262) classifies a system’s ability to withstand shocks. The highest rating, IK10, equates to an impact of 20 joules.

Some luminaires on the market not only reach this level but exceed it, both in the body and in more vulnerable parts like diffusers, poles, or service doors. Certain current solutions are tested up to 50 joules, offering durability that drastically cuts breakage or replacement costs.

Coastal areas: an especially hostile environment

Proximity to the sea poses a tough technical challenge for any outdoor product. The combination of salt, constant humidity, wind, and intense sunlight accelerates corrosion in metal materials, even when coated.

Maintenance in these settings usually involves periodic repainting, inspections, and reapplication of anti-corrosion treatments — a high and recurring cost for municipalities.

An alternative strategy is to use intrinsically corrosion-proof materials, like engineering polymers. These solutions require no paint, varnish, or extra protection: resistance is built into the structural material itself.

Extended salt spray tests (over 2000 hours) have shown that these materials maintain their physical and visual integrity even after years of direct exposure. This ensures stable, reliable lighting systems in ports, promenades, beaches, and coastal areas, with no need for corrective or preventive maintenance.

Not just mechanical: durability against overvoltages

Although efficient, LED luminaires are sensitive to electrical disturbances such as transient overvoltages caused by grid operations or atmospheric/electrostatic discharges. Such events can cause premature failures, component loss, or degradation.

Some market solutions incorporate structural immunity strategies, such as:

- Class II insulation without grounding (avoids discharge channels).

- Non-metallic enclosures (prevents charge buildup).

- Protected, seamless internal architectures.

This approach reduces the need to replace damaged modules and protects the electronic investment over the product’s lifespan.

Fewer interventions, fewer resources, lower environmental impact

Durability is also a sustainability factor. The fewer interventions a system requires, the smaller its operational footprint: fewer trips, less waste, fewer spare parts, and lower energy consumption.

Moreover, some manufacturers — like ATP — have chosen to use recyclable materials, maintain ISO 14001-certified production processes, and design systems that reduce glare and preserve the night sky, further amplifying the long-term positive impact of the lighting.

Backing up the technical with commitment and warranty

A manufacturer’s warranty can serve as a reference to evaluate confidence in the real durability of its products. In this sense, a 10-year coverage without restrictive conditions (regarding humidity, salinity, temperature) is a clear signal of technical backing, beyond theory.

Durability proven over time

Estimated lifespan in datasheets is one thing. What’s verified after years in public service, without maintenance or failures, is quite another. Real durability is not a marketing promise: it’s the result of every technical decision made in design, material selection, sealing, and structural protection.

For public lighting managers, this factor is anything but secondary — it can entirely determine a project’s overall efficiency and the perceived quality of service.

Press contact:

Julio Aparicio

ATP Lighting

comunicacion@atpiluminacion.com

Copyright © 2016 ATP Lighting Inc. All rights reserved. ATP Lighting, the ATP Lighting logo and all trade names listed on this website with the ® symbol are registered trademarks of ATP Lighting.

![[...]](https://www.atpiluminacion.com/xtra/imgs/loading.gif)